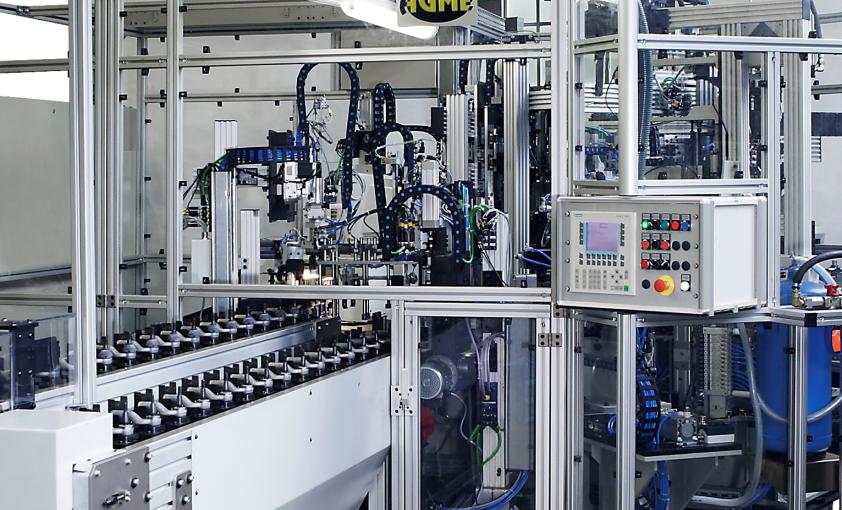

Processes

- Assembly, rolling over and greasing of ball joint sub-assemblies

- Machine built-in capablity for 3 different models

Technologies

- Rotary transfer with 8 workstations

- Palletized system to feed and position parts

- Design and manufacturing of special fixtures

- Control by PLC

- Automatic feeding and assembly of housings, studs and shells

- Pressing and greasing of subassemblies

- Automatic feeding and marking of covers

- Automated rolling over utilizing double rolling head.

- Built-in process control of rolling over

- Automatic reject management including selection OK and NOK subassemblies

- Unloading by a manipulator

Advantages

- Integration of assembly, greasing and quality control processes of ball joint sub-assembly into a single machine

- Complete automation of all processes except for manual loading of the pallets

- Optimization of the assembly process that results in significant improvements in productivity

- EC declaration of conformity