The riveting management can be done through different agile, efficient and easy to use control systems. All electric cabinets integrate a PLC to command the riveting machine.

C-500 standard control

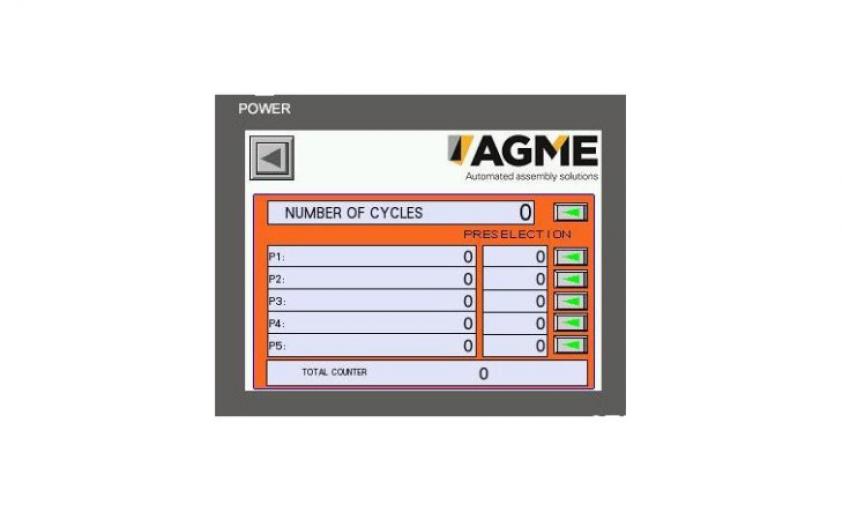

It is the basic equipment of all riveting machines. Among other parameters, the riveting time and the counters can be adjusted. C-500 standard control main technical features are:

- Manual / semi-automatic selector switch.

- 7 " touch screen

- General cycle counter and 5 programmable counters for warnings

- Hourly counters for the last 8 hours of production

- Counters by turns of the current day and the day before

- Riveting time control 0 to 5 sec

- Error warning system

- Integrated Siemens PLC.

- Two hand control.

- Possibility of switching via Ethernet with external siemens PLC.

- 400V, 50HZ Voltage. Optionally other voltage.

AC Quality assurance systems: AC1 and AC2

The AC systems control the riveting pressure and course. The return is performed from a parameter that is electronically introduced. It can differentiate OK and NOK parts, taking into account the indicated parameters.

- The AC1 quality assurance system is based on the absolute measure of the riveting head position. It measures the riveting course from the machines resting position.

- The AC2 quality assurance systems include a mechanical hold down device to determine the reference surface for the riveting course measure

Electric cabinet for the RA-NCD flexible riveting centres.

This electric cabinet makes possible any number of riveting positions, just introducing the sequence of the riveting process. It has an editable HMI to manage the programs and the quality assurance system can be also integrated as an option.