Our technical team, which has huge experience and know-how in developing efficient riveting solutions of a high quality, looks into the technical specifications of every part and process and determines which the best riveting machine is for meeting the production requirements, even exceeding the clients expectations.

In our laboratory, our technicians make several riveting tests with your parts until they get an optimum result. After this, our designers and production experts modify our standard riveting machines or riveting heads and adapt them to the required process and the component. All the additional accessories that are necessary to get the required result are also designed and built in our premises.

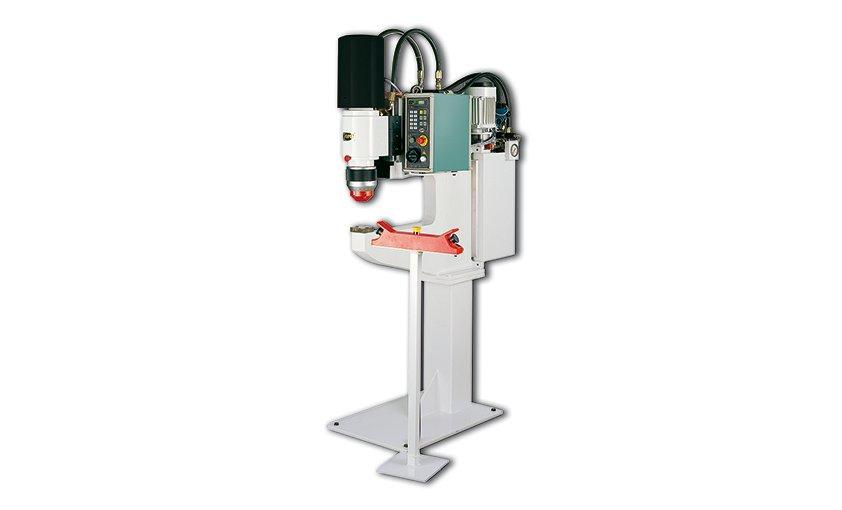

We develop special riveting machines, custom-made riveters with the following features:

- Special dimensions: special throat, frame …

- Side fitted motor riveting head unit with frontal holding

- Double riveting machines to both sides part riveting at the same time

- Special purpose heads:

Rolling over units with double or multiple roller burnishing heads to achieve the form you require

Riveting heads with double or multiple riveting tools to reduce the production time.

Heads with more riveting speed than standard.

Different radius heads, special hold down devices … - Special orbital riveters when necessary.

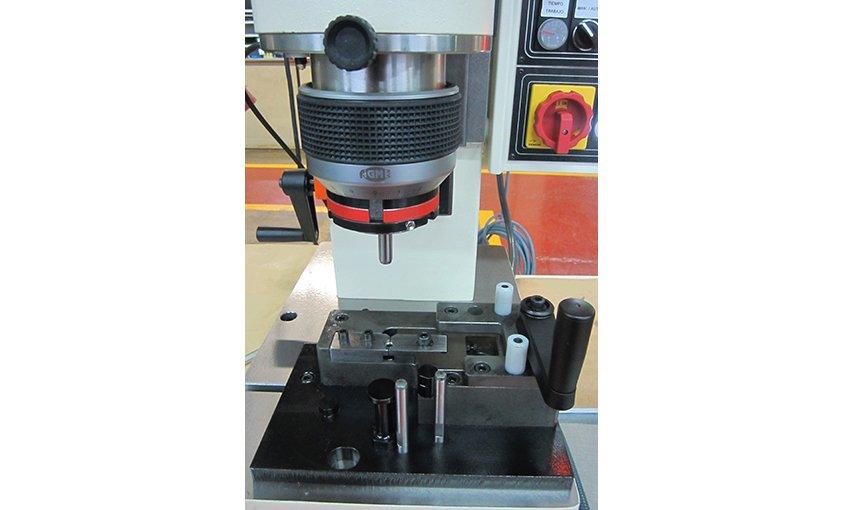

- Special tooling and fixtures that are designed and manufactured at AGME.

Fixtures mounted on manual or pneumatic slide fixtures

With poka-yokes, model detection, holding clamps, etc. - Special riveting tools

To get different riveted head shapes, semi tubular rivets, with special non-rotating systems. - Parts automatic feeding systems into the fixture.

- Riveting machine´s positioning system in different points by pneumatic or electric chariots.

These possible adaptations turn our standard riveting machines into special riveting solutions that are developed to meet every process and part technical specifications.