Processes

- Automated assembly of seat tracks

- Capability to assemble several track models

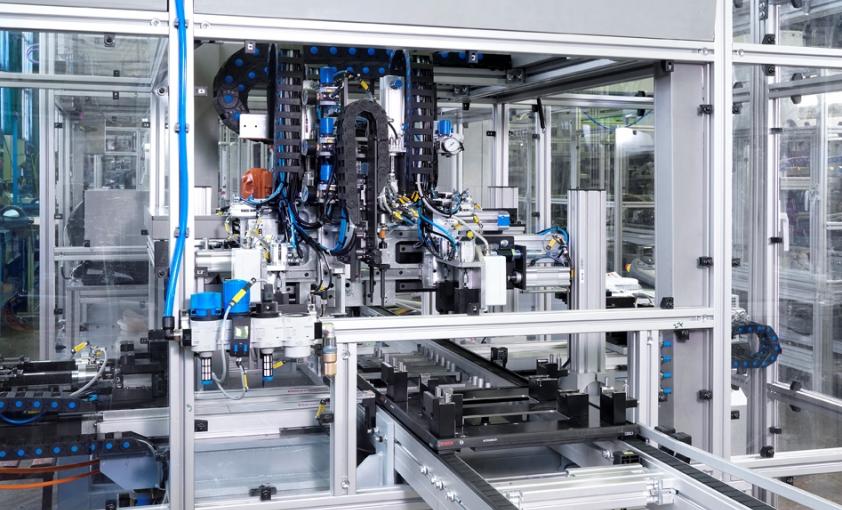

Technologies

- Linear transfer with 15 workstations

- Palletized line with special fixtures

- Poka-Yoke of pallets to ensure correct positioning of parts

- Component presence and model control using laser sensors

- Track lubrication by incorporated spraying system

- Assembly of upper and lower tracks

- Crimping and burnishing

- Tracks liberation and slide efforts checking

- Automatic part traceability and labelling with a robot

- Identification and separation of OK and NOK parts

Advantages

- All seat tracks assembly processes including effort and quality checks are integrated into a single machine.

- Automation focuses on both the repetitive and critical processes (quality tasks that require more force or precision control).

- Production cost reduction and productivity increase by reducing the cycle times

- Repeatability quality assembly and control with the best quality assurance systems

- EC declaration of conformity