Processes

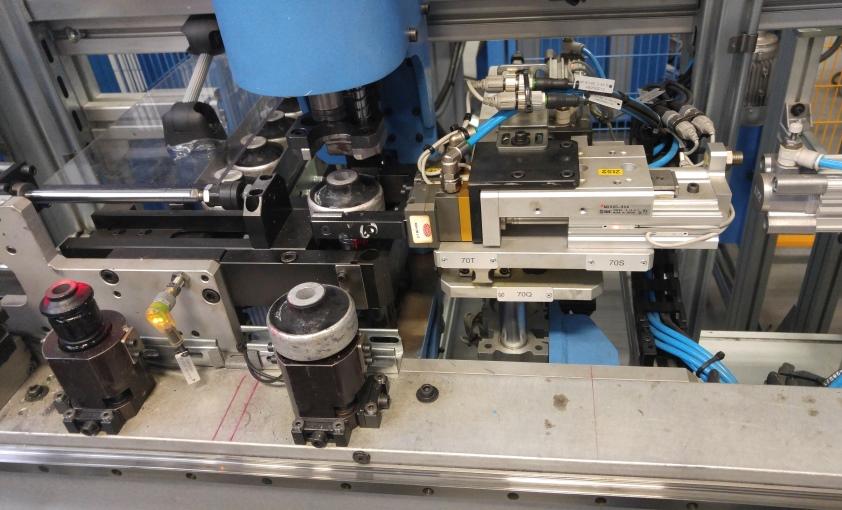

- Automatic assembly of the bushings into the suspension arms

- Assembly of 4 different models

Technologies

- Automatic feeding and handling of components

- Robotized handling of the suspension arms and the bushings

- Automatic greasing of components by dosing

- Design and production of special tooling and fixtures per model and hand

- Control of component and model presence by sensors

- Automated insertion of bushings into the supension arms by servopresses

- Stroke and force control

- Programming and process automation

- Marking of suspension arms

- Control of the machine by an Automata

Advantages

- One single machine to perform the assembly, greasing and control of 4 different models

- Flexible machine capable of processing different models, just changing the tooling, fixture and the programm.

- Compact and robust machine that does not require much space in the site

- Process control that guarantees the final quality of the suspension arms

- Optimization of the production times

- EC declaration of conformity