Processes

- Riveting, greasing, insertion of bushings and marking of recliners

- Machine that requires two operators

Technologies

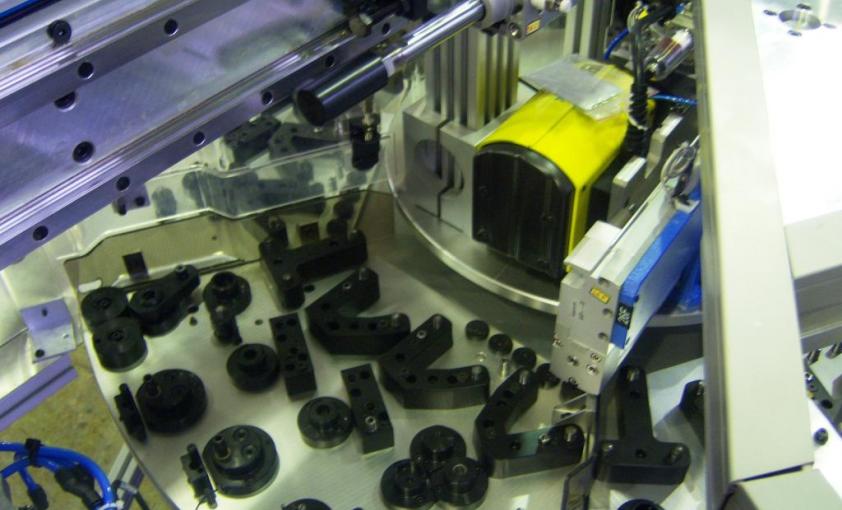

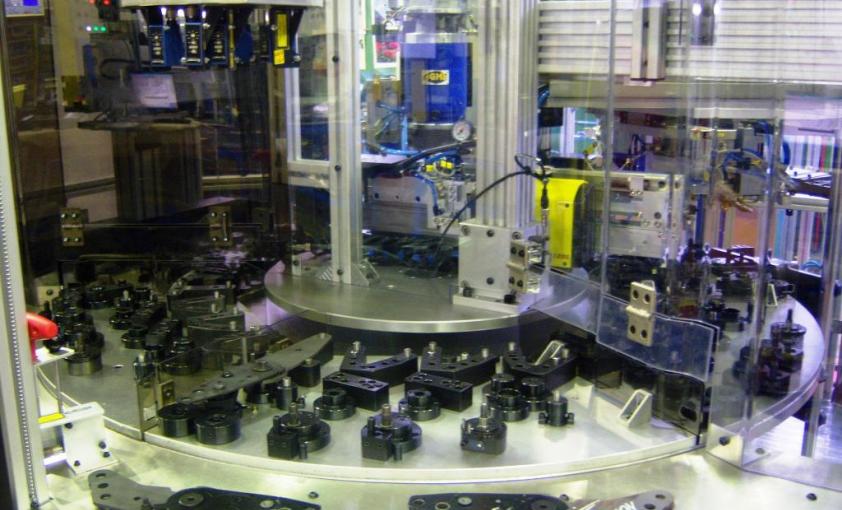

- Rotary transfer with 6 workstations

- Palletized components on a rotary plate

- Design and manufacturing of special fixtures on pallets

- Parts presence detection by laser

- Control by artificial vision

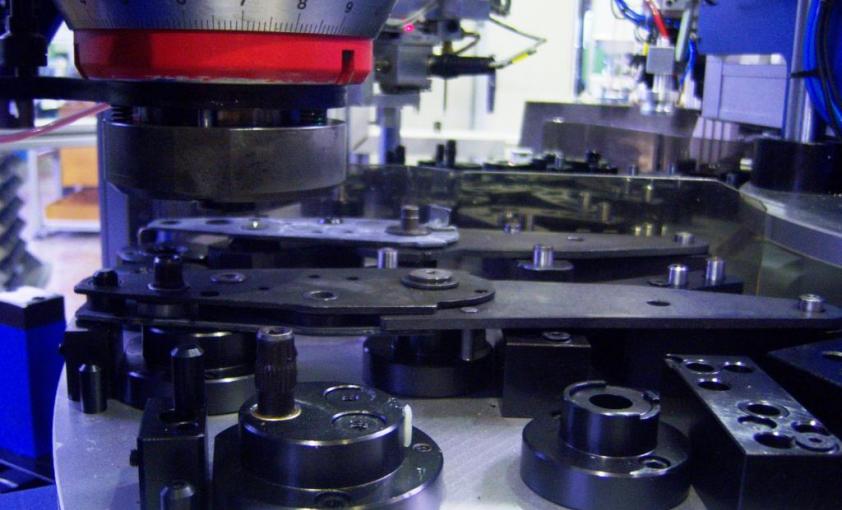

- Riveting of 5 positions with 2 controlled axis

- Bushings insertion by a pneumatic unit

- Greasing with volumetric doser

- “Num” numerical control

- Recliners automatic marking by scratching system

- Automatic unloading of recliners with OK / NOK parts selection

Advantages

- Integration of all processes into one single machine: recliners assembly, greasing, control and marking

- Adaptation to the client automation requirements

- Robust and compact machine that saves room in the factory

- Flexible machine that is valid for different models

- Artificial vision system that optimizes the parts control process

- EC declaration of conformity