Processes

- Latches assembly, greasing and effort control with 2 operators

- Valid for right hand and left hand latches

Technologies

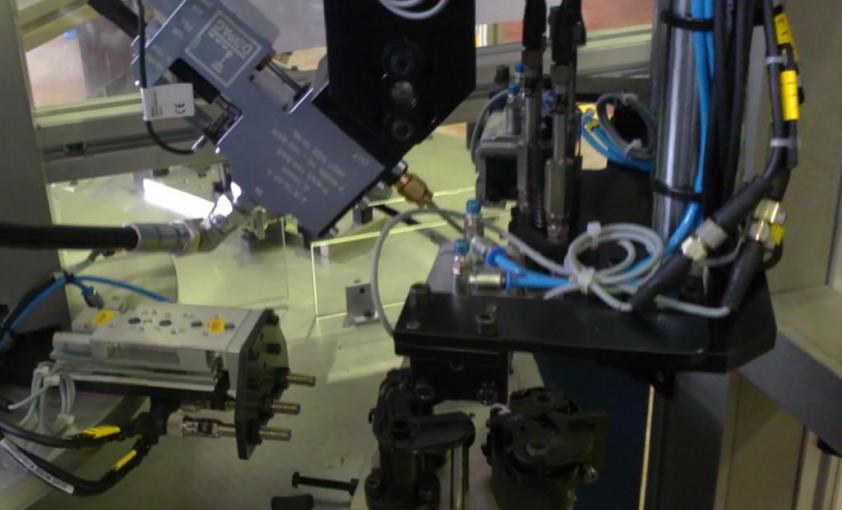

- Dial transfer with 6 workstations

- Design and manufacture of special tooling and fixtures

- Components presence control by inductive sensors

- Automatic insertion of bolts and bushings by pneumatic presses

- Automatic greasing of bushings and claws by dosing system

- Final assembly of parts by a hydraulic press

- Control of the latch release and locking force

- Control by automata

- Quality assurance system

- Automatic unloading of latches with OK / NOK parts selection

Advantages

- Robust and compact semi-automatic machine that saves room in the site

- Integration of all latch assembly, greasing and control processes in one single machine

- Optimization of the production time

- Customized flexible solution that is valid for both hands: right and left

- Efficient and innovative system for controlling the release and locking force after the latch assembly

- Process control that guarantees the final quality of the assemblies