Processes

- Greasing and assembly of ball joints

- Capability for several model types

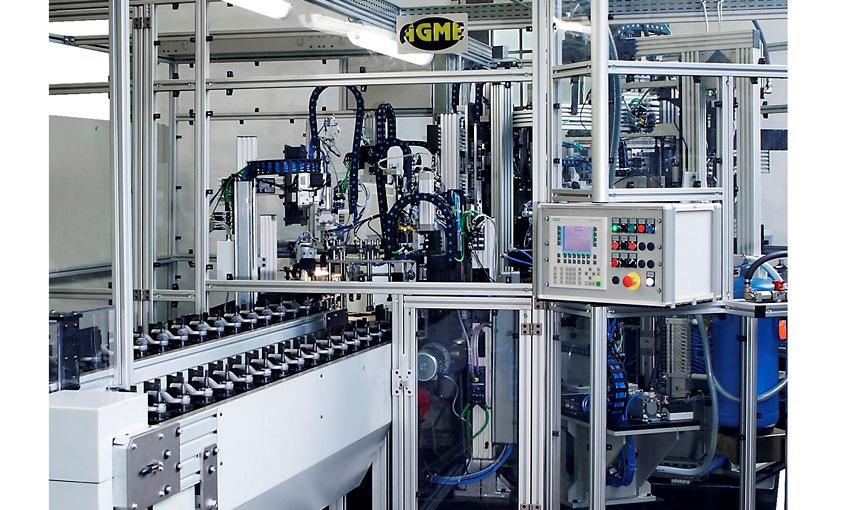

Technologies

- Rotary transfer with 10 workstations

- Palletized system to feed and position parts

- Design and manufacturing of special fixtures

- Automatic feeding of components from pallet to the rotary transfer

- Studs straightening by a double fork system with angle control

- Torque control

- Automatic feeding of the guiding cone on the stud

- Greasing of components by dosing system

- Components automatic feeding and assembly by manipulators, linear transporters, selection devices and pincers

- Seal control with a leak tester

- Components position control

- Automatic loading of OK parts on pallets by a manipulator

Advantages

- Integration in one single machine of all ball joints assembly, greasing and control processes

- Complete automation of all processes except for the subassemblies manual feeding on the pallets

- Optimization of the assembly processes, resulting in cycle time reduction and productivity increase