Process

- Automated assembly, torque control and marking of car hood hinges

- Assembly of two models LH and RH

Technologies

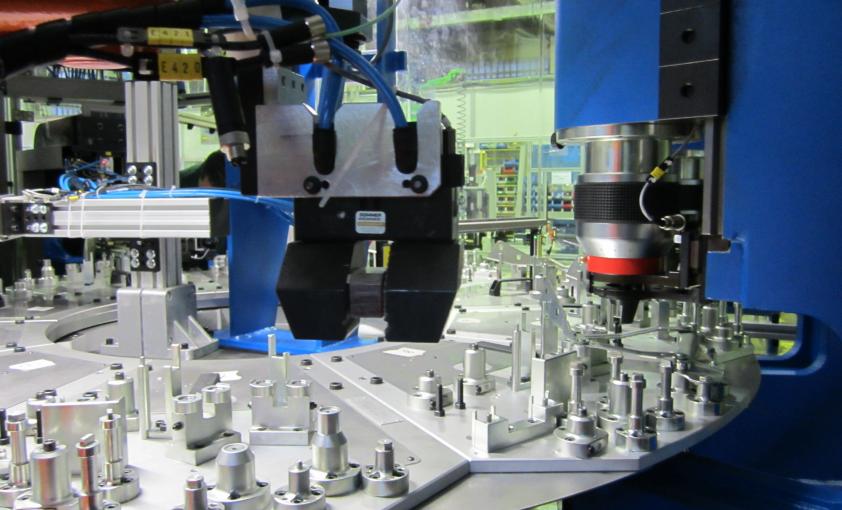

- Design and manufacture of tooling and fixtures

- Automatic feeding of components

- Presence control with lasers

- Correct load control with poka-yokes

- 90º flanging with hydraulic units and part calibration

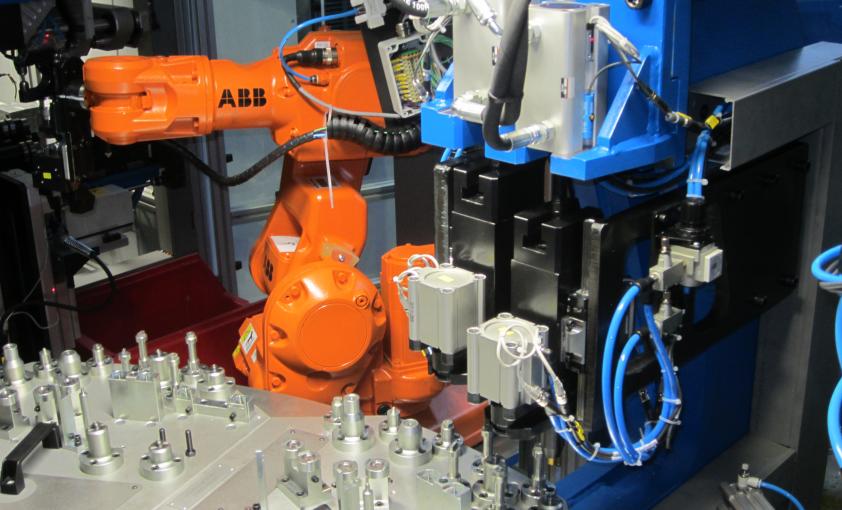

- Automated and robotic pneumatic manipulation

- CNC riveting of several positions

- Torque control

- Scratch marking

- Automatic bolt insertion

- Programming and process automation

- Automatic evacuation with OK and NOK parts selection

Advantages

- Optimization of the hinge assembly process with significant increase in productivity

- Flanging and gauging of bushings to guarantee top quality

- Automated riveting of various rivet positions

- Maximum control of the final quality of the assembled hinge

- Integration of all automatic assembly, control and marking processes in a single machine

- Flexible, compact and robust machinery, which optimize space on the shop-floor

- EC declaration of conformity