Processes

- Assembly, rolling over and greasing of double head links, stabilizer bars

Technologies

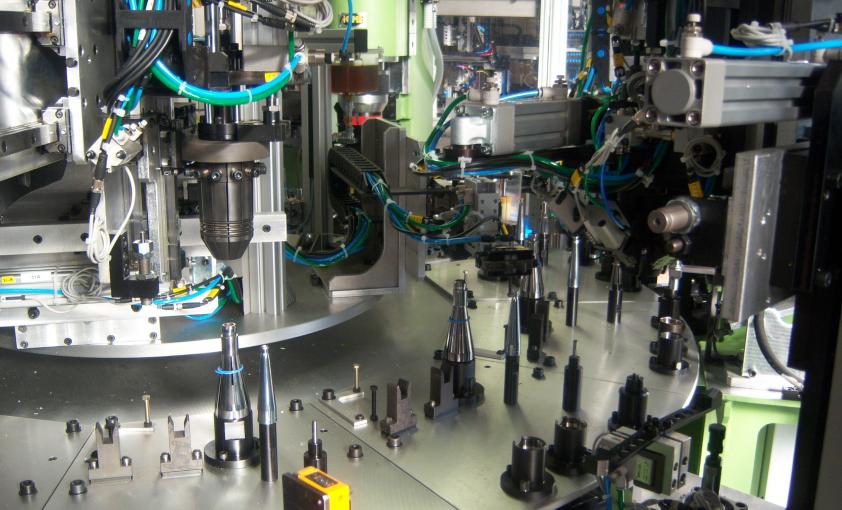

- Rotary transfer with 12 workstations

- Fixture controlled components on a rotary plate

- Design and manufacturing of special fixtures

- Automatic feeding of components

- Control by PLC

- Automatic rolling over of housing

- Automatic greasing of components by utilizing dosing technology

- Components presence, torque and air seal control

- Automated assembly of all of components

- Automatic unloading of stabilizer bars with reject management

- Built-in 180º turning to allow assembly of both sides of parts

Advantages

- Integration of all stabilizer bars assembly, greasing and control processes in one single machine

- Optimization of the assembly process that results in significant improvements in productivity

- Assembly of both sides of the link by automatically rotating the link 180º just after completion of one side.

- Air seal check during link assembly