Process

- Simultaneous riveting of brackets to seat tube links and marking

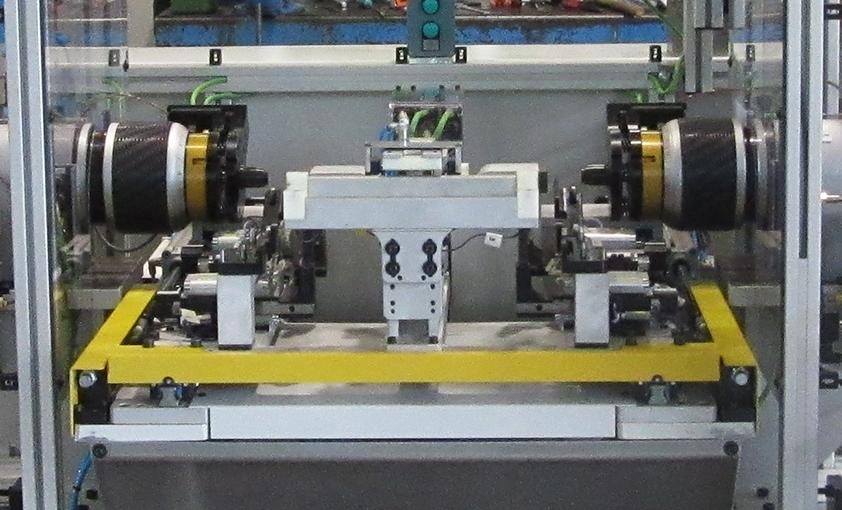

Technologies

- Design and manufacture of fixture with pneumatic slide

- Traceability of components with barcode reader

- Presence and model control of components with inductive sensors

- Simultaneous riveting of links with horizontally mounted facing AGME riveting heads

- AC2 riveting process control with pressure and stroke transducers

- Separation of Ok and NOK parts

- Component marking with labelling machine

- Process automation

- PLC control

Advantages

- Integration of 2 riveting processes, control and marking on one only machine

- Riveting of both links at the same time optimizing production times

- Increased production flexibility by using two riveting machines facing each other

- Increased productivity and lower manufacturing costs

- Homogeneity of parts and high-quality standards

- Flexible, compact and robust bespoke machine

- CE certification of the machine