Processes

- Riveting of hood hinge sub-assemblies

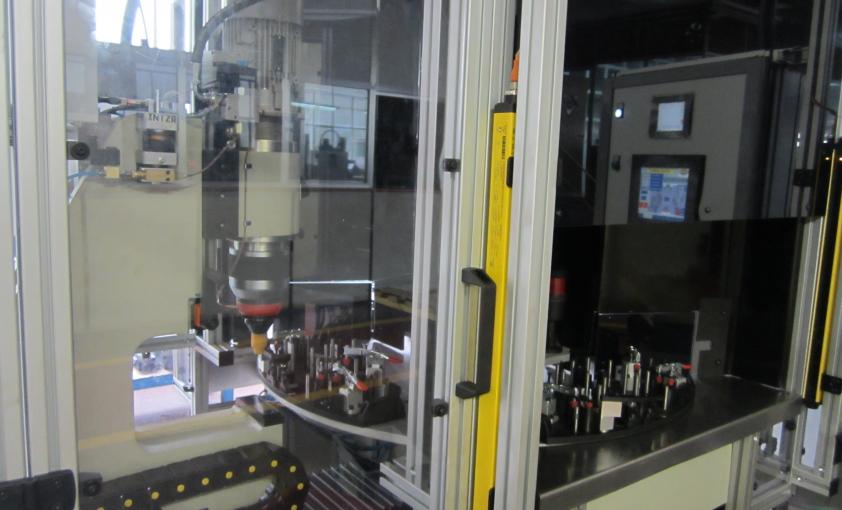

- Semi automated riveting machine with 2 operators

Technologies

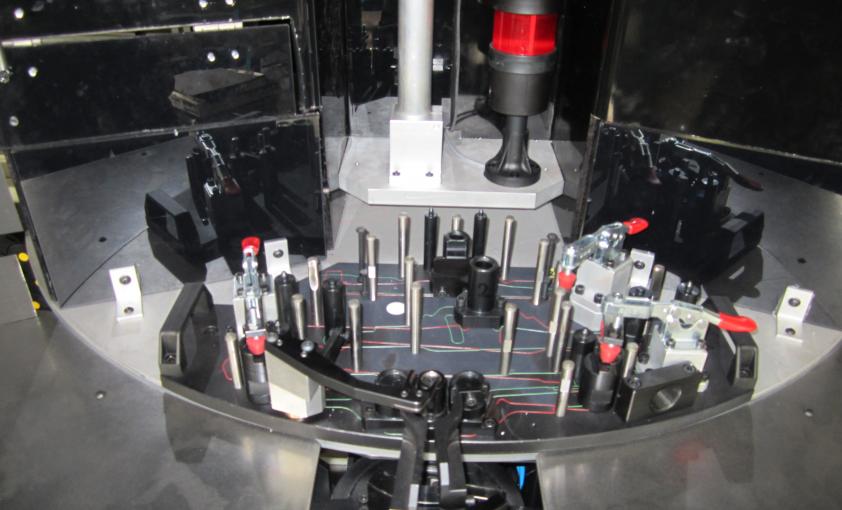

- Rotary transfer with 4 workstations

- Design and manufacture of the required special fixture

- Incorporation of Poka-Yoke to ensure part type and location

- CNC riveting of multiple locatios and positions

- Integrated process control and quality assurance

- Riveting automation controlled through Omron PLC

- Model identification and management by laser technology

- Spring tensioning device integrated into the fixture

Advantages

- Compact, "low footprint" machine that minimizes floor space used

- Capacity to rivet different sub-assemblies models

- Spring tensioning to aid manual loading