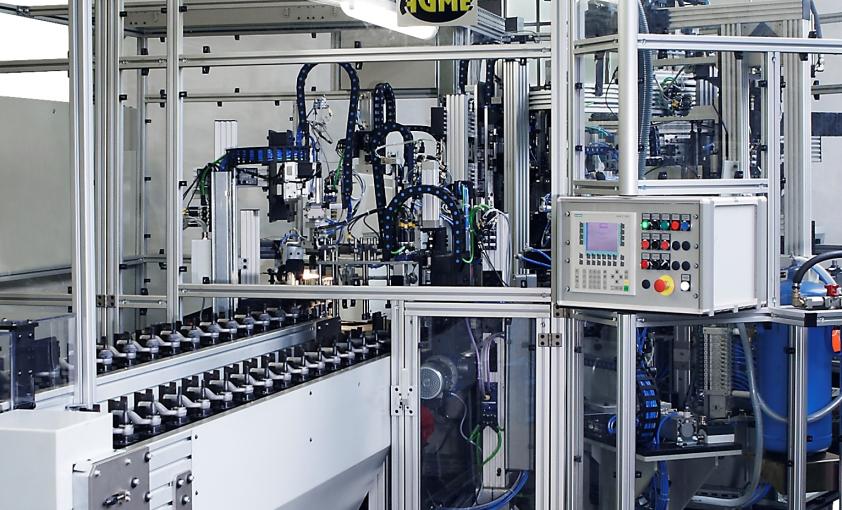

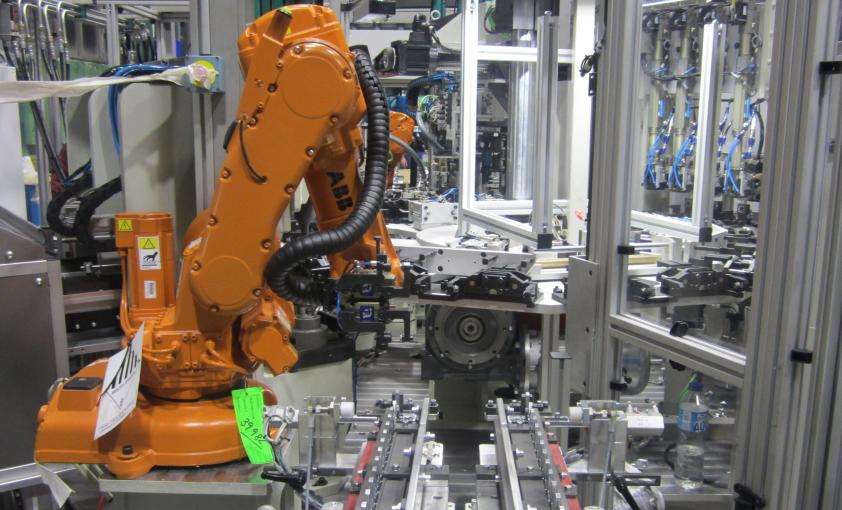

AGME integrates the most advanced technologies into our special purpose machines in order to work and control the production processes in an autonomous way. The main purpose is to maximize the productivity standards and optimize the processes. We also develop connectivity solutions between different machines, using a team of engineers that are specialized in programming/software e interconnectivity.

The level of automation for each assembly solution depends on the clients’ technical specifications. The special purpose machines can incorporate as many manual, automatic or semiautomatic workstations as the industry requires. Our core competencies in these fields are:

- Control systems (PLC, micro controllers)

- Any type of sensors and actuators

- Programs and applications for PCs to check and control the production processes

- Human-Machine Interfaces (HMI): graphic and intuitive systems to communicate with the PLCs and other computers.

- Data transmission and collecting systems (traceability and data bases). Bar code and data matrix reading and marking

- Development of data analysis specific software

- Interconnectivity between machines: Ethernet, intranet, RFID …

Our interconnectivity solutions include: from production data local storage systems in machines that are connected by intranet, to complex solutions that incorporate total connectivity systems between machines located in different factories and different internet servers.