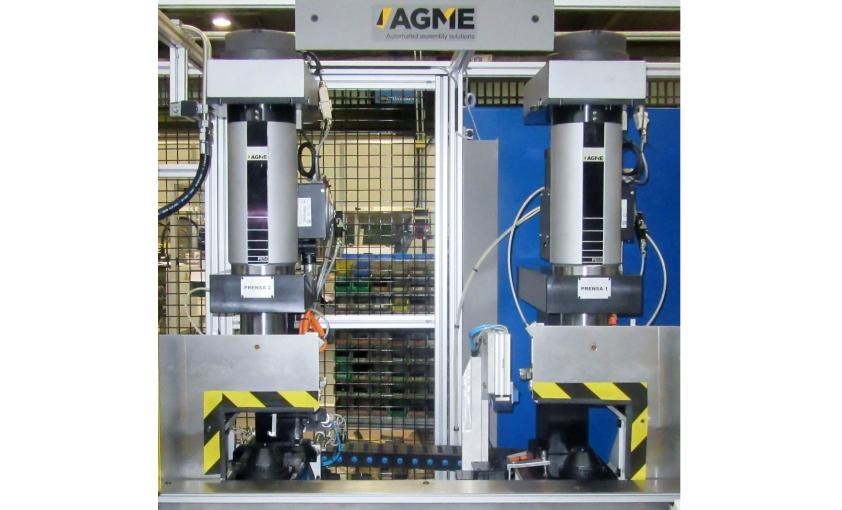

AGME manufacture special machines incorporating AGME servo technology for the automotive industry. These customized solutions are tailored to the specific needs of each process and component dimensions, production times, control functions and data management.

We have the full capability to deliver complete turnkey solutions, every stage of the design and manufacturing of the special machine, to the commissioning in the clients premises. Tooling and fixtures are also designed, developed and manufactured at AGME.

The integration of electrical press technology is becoming even more critical due to the increasing requirement for constant monitoring of the results and the demand for greater precision and repeatability in the production processes of the automotive industry.

These bespoke solutions offer complete control and monitoring functions: Load across the full stroke, distance from contact, contact position, final position and final load. The results are stored in a database that can be exported to a PC, guaranteeing the full traceability of the process.

AGME servo presses have multiple applications in component insertion operations:

- Insertion of silent blocks in suspension systems, housings, shock absorbers, antivibration systems

- Insertion of screws in wheel hubs

- Introduction of bearings and axles into windshield wipers

- Other similar processes