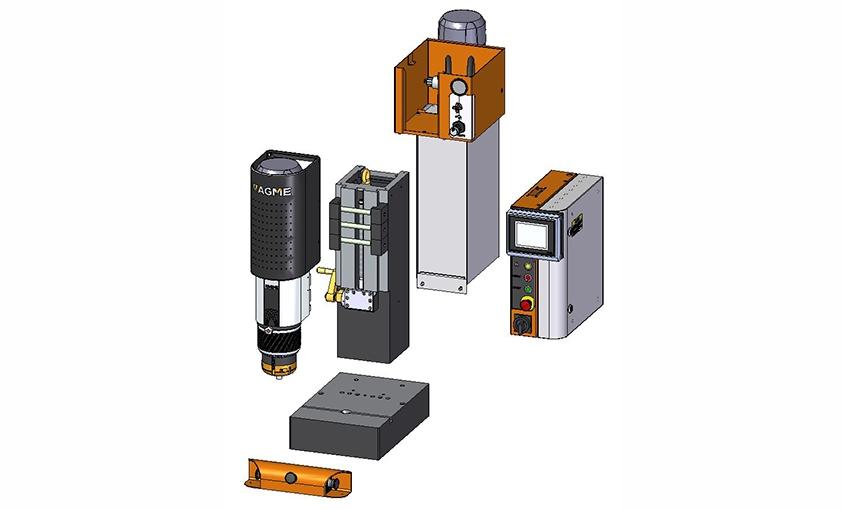

Very good acceptance of the fourth generation of AGME riveting machines in the industry, radial riveting equipment with significant improvements in performance, design and finish.

Following our policy of excellence pursuit, we have implemented in our standard riveting machines considerable advances in durability, reliability, performance and ergonomics. In addition we have also achieved notable improvements in flexibility and respect for the environment.

AGME RA riveting machines continue to be the best solution to obtain the highest quality joints, effectively solving any assembly need: from the deformation of small rivets to obtaining large heads with different geometries. With a more current and innovative design, our new riveting machines integrate, among others, the following technical features:

- New larger electrical cabinet with 7” touch screen and a much more intuitive interface (HMI).

- Possibility of program modifications and extensions (PLC).

- Improvement in the distribution of the magneto-thermal switches with cable conduits.

- Improved maintenance and accessibility to the electrical cabinet interior.

- Longer service life of the riveting machine thanks to increased load capacity

- Improved automatic lubrication system

- Front access to regulation systems

- New two-hand control with plug-in terminal and concealed passage option.

- New electric motors complying with the European energy efficiency standard IE

The most important global manufacturers of automotive components have already integrated them into their special assembly machines in Europe and Asia.

Contact us to see first-hand the improvements of our fourth generation of RA series radial riveting machines