With over 50 years of expertise in riveting technology, AGME is leading an innovative R&D&I project that sets new standards in automation and precision in mechanical assembly processes.

Specifically designed for key industries such as automotive, metal fittings, and industrial equipment, our new solution integrates technological advances that significantly improve the efficiency, flexibility, and quality of automated component assembly using radial and orbital riveting technologies.

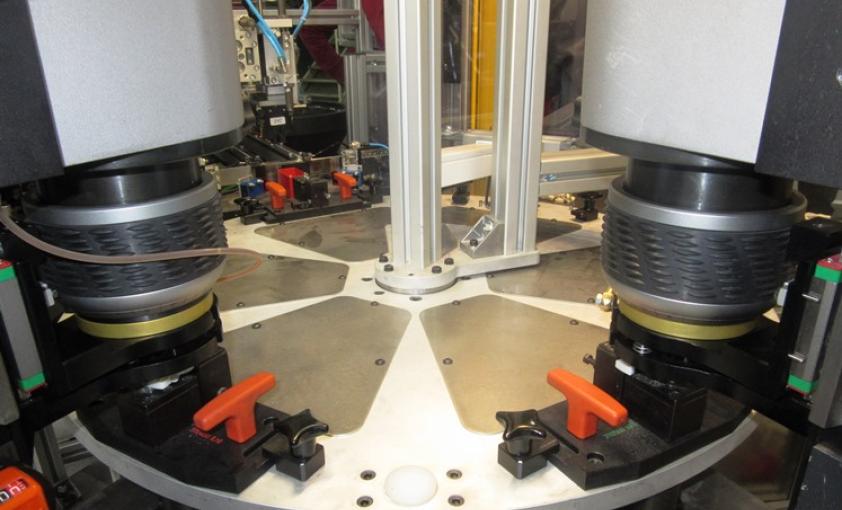

High-Precision Riveting with Advanced Automation

The system integrates electric X, Y, Z axes and an electric riveting head to ensure unmatched accuracy and adaptability across various riveting setups.

It also features an intelligent process control system with an intuitive interface, allowing operators to program the machine without prior knowledge. An automated riveting tool change system further reduces downtime and boosts productivity.

It offers great flexibility for customised riveting processes

Our engineered solutions is designed to accommodate multiple riveting position configurations with quick changeovers and no complex adjustments.

This flexibility, combined with automated riveting tool changes, reduces production times by up to 15% and improve joint quality by 20%. The result is a significant increase in operational efficiency and cost savings for manufacturers.

In-House Engineering, Guaranteed Quality, and a Sustainable Vision

This project highlights AGME’s ability to design and manufacture fully customized automated riveting solutions, backed by in-house production and strict quality control.

In addition to strengthening our technological leadership, this innovation will create highly skilled jobs and support more sustainable manufacturing by reducing material waste and energy consumption. AGME continues to set the benchmark in industrial innovation, engineering excellence, and global competitiveness.