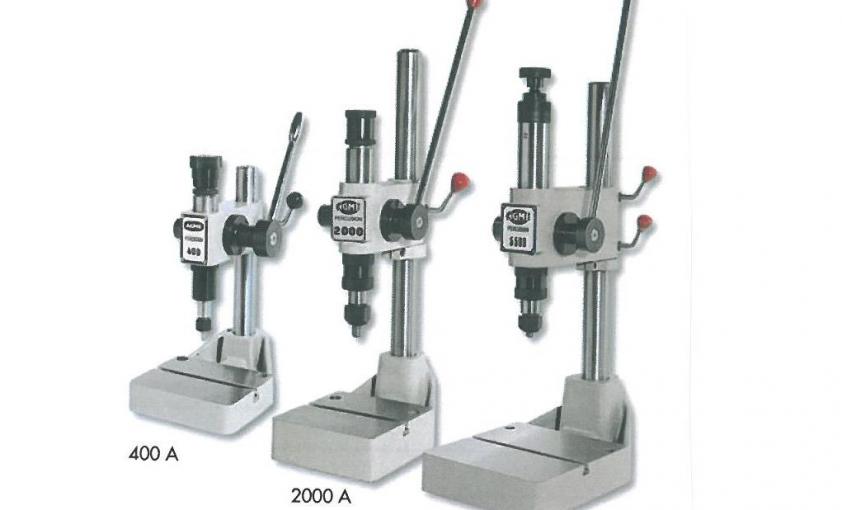

The most common applications of the rack and pinion presses models 400, 200 and 5500 CL are: assembly of bushings, bearings, plate deforming and general assembly processes. The manual percussion presses models 400, 2000 and 5500 A are appropriate for riveting, bending, marking, cutting, forming and assembly processes.

AGME manual presses can also incorporate quality assurance systems to control the processes and monitor the force and the stroke of the pressing operations. Precise and reliable measuring technology is the key to comprehensive quality assurance for assembly, joining and pressing processes. This approach makes the process independent of the respective operator and the quality of the results is 100% guaranteed.

AGME manual presses with quality assurance systems control all processes performed by the machine and make it possible a secure separation and acknowledgement of NOK/OK parts.

Technical features of the quality assurance system:

- Displacement sensor

- Load cell to measure the force

- Display screen. XY-monitor to evaluate OK/NOK. 16 measuring programms. Dig-IO (24V), Ethernet TCP / IP

- Colour touch screen. Intuitive HMI