Its agile conversational human/machine interface system is very simple to work with. It is possible to program this automatic riveting machine without specific CNC knowledge. A programmer can very quickly become familiar with the interface and learn how to create, edit and delete programs.

AGME flexible riveting centre´s control is done by a Siemens 1500 PLC that manages all part programs and the machines signals by delivering the exact positions where we want to perform the riveting process, to the servo-drivers. The programs that are registered enable to process any number of the riveting positions and also just passing positions (to avoid obstacles).

This control method enables us to do the following works:

- To add, modify and delete the part programs that are assigned to each model. This means a total flexibility when you have to manage different riveting processes.

- Within the riveting programs, to modify and create new riveting points, positions to move, modify riveting speed and many others

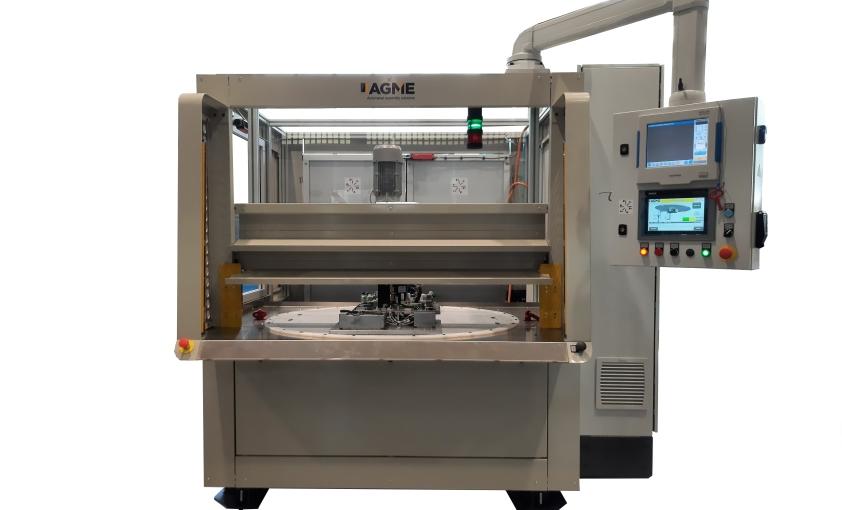

The standard equipment includes AGME pneumatic or hydraulic radial riveting machines. The riveting is with mechanical stop and optionally a third controlled Z axis, and/or the AC1 or AC2 quality assurance systems can be integrated.

Among all these models with 2 or 3 servo controlled axis, you can find the best solution that will result in much more flexibility when riveting and changing production parameters. They offer great savings when compared to standard single station machines.